The filter bag is typically made of textiles like needle-felt melt-blown or woven materials of mono- or multi-filament fibers. Baghouse Filtration Menardi Filters Your Filter Solutions Provider.

Pulse Jet Bag Filters The Ultimate Faq Guide Filson Filter

Collector by calculating the total filter area of each filter bag diameter x 314 x length 144 for number of inches in a square foot filter cloth area and then multiply that figure by the total number of bags in the collector.

. FBX Filter Bags can also be made using a wide variety of geotextiles depending on overall size requirements the type of sediment being. They are used for dredging operations construction sites or places with a high water table near the shoreline. Single Bag Filter Housings Duplex-Skid Systems Multi-Bag Filter Housings.

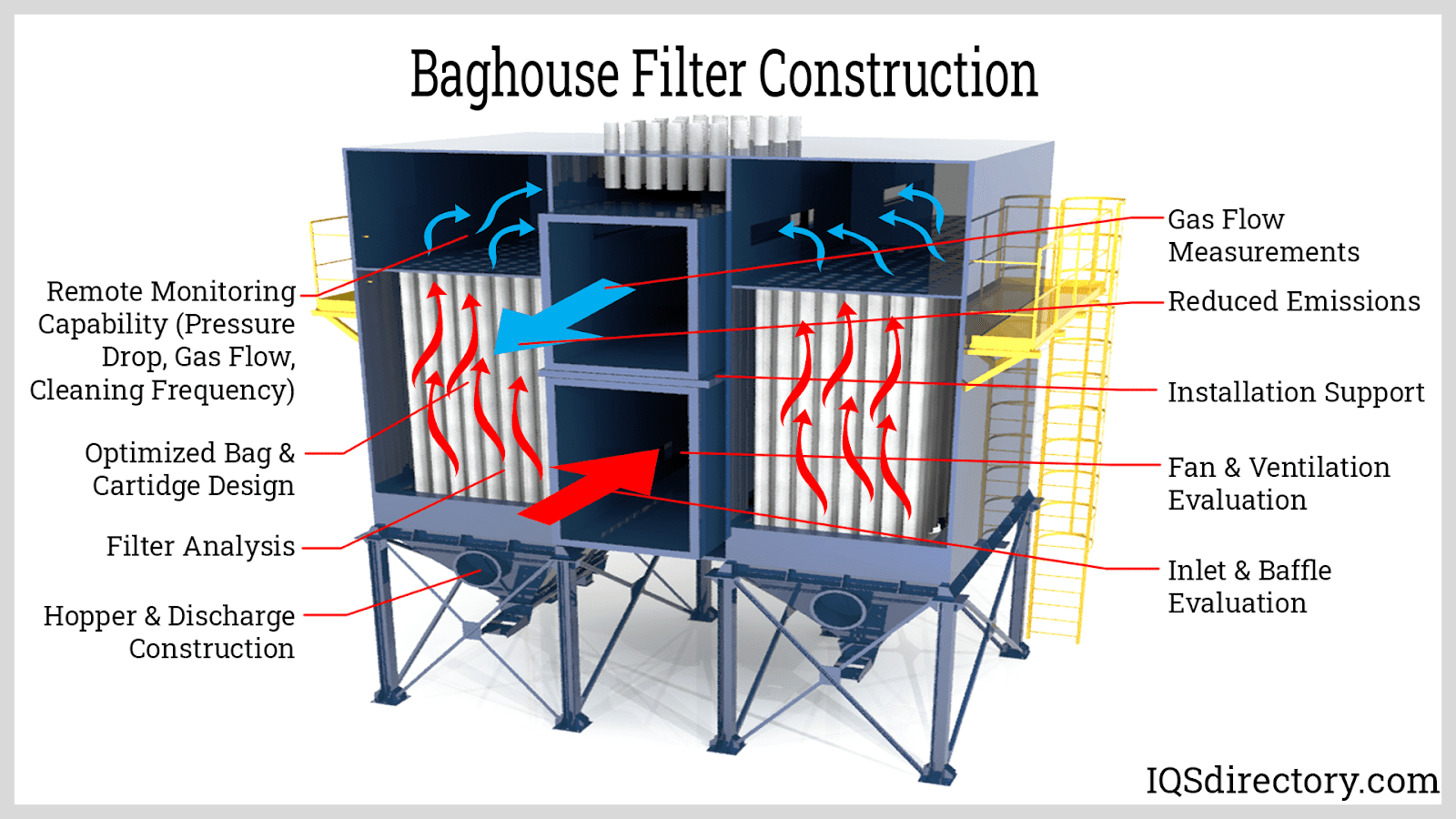

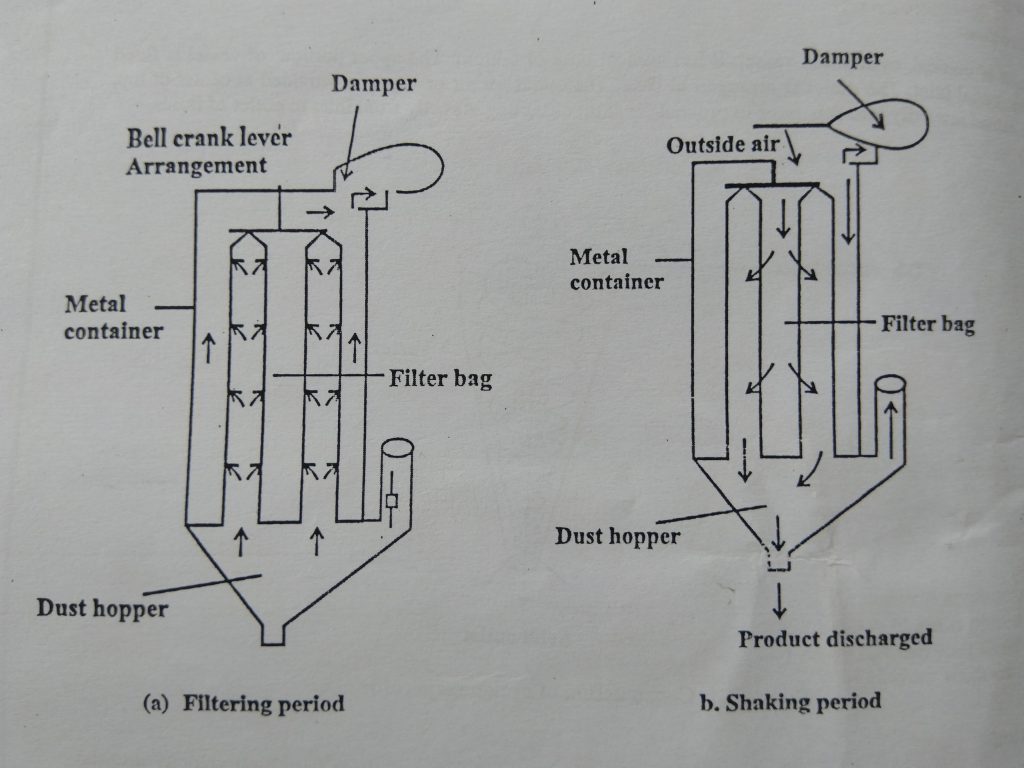

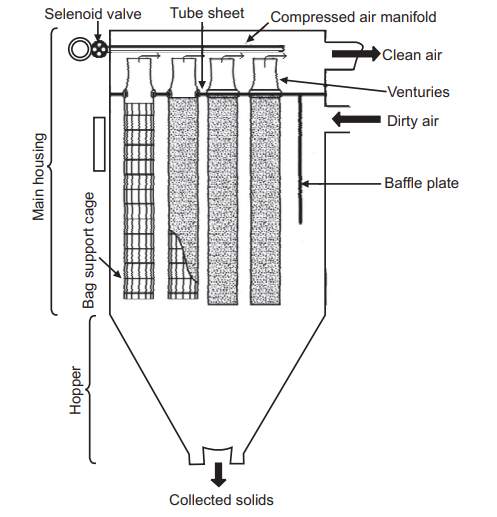

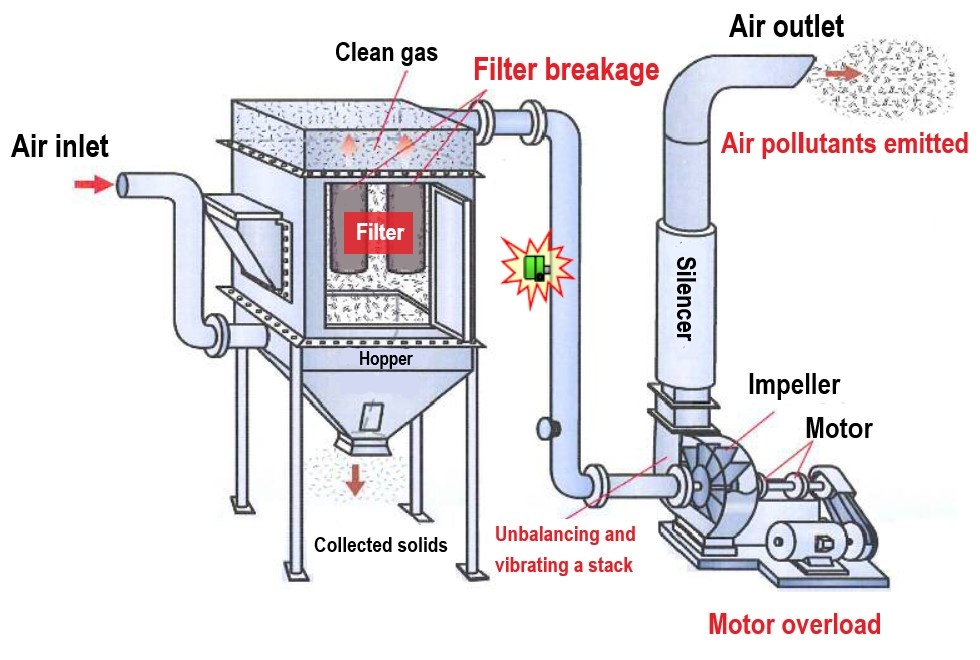

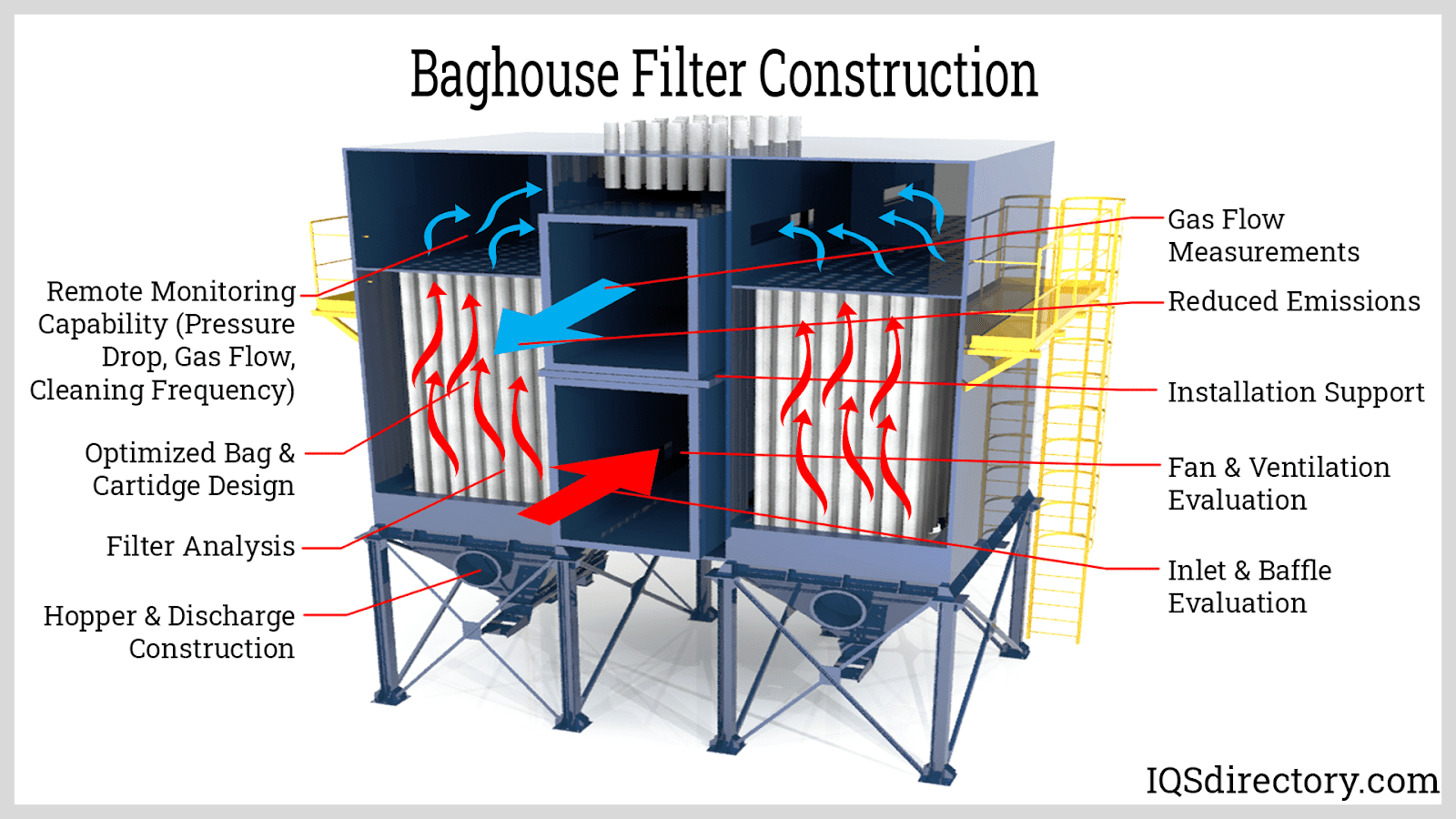

A bag filter also known as a bag house filter or fabric filter is an air pollution control device and dust collector that removes particulates or gas release. Fabric filter media must be compatible both physically and chemically with the gas stream and system conditions. Easy to install use and empty these bags help remove sediment so that flows from your site remain clear and free from debris.

These steel filter bag housings have heavy duty construction and are more durable than our other metal housings. Microfiber filter bags have spunbonded covers to prevent fiber migration. Often implemented in areas where sediment basins are impractical dewatering bags work to filter sediment out of the water before it discharges from your site.

Typical applications include the dewatering of construction and excavation sites as well as dewatering lakes and ponds. ECOGRACE provide key sollution for air pollution control dust filtration system. Nonwoven materials can further be divided as felted or membrane.

These bags should be sized accordingly based on the pump flow rate and type of sediment. The filter bag is inserted into a restrainer basket. Filter bags used in the industrial dust collection industry can be made of woven or nonwoven materials.

FBX-80 is Carthage Mills standard Filter Bag and is manufactured with FX-80HS a sturdy 8 ozyd2 nonwoven geotextile. Take the CFM of the system and divide it by the total filter cloth area to get your air to cloth ratio. CONSTRUCTION Standard filter bags are typically manufactured with a metal ring either galvanized carbon steel or stainless steel sewn in the top of the filter bag.

Bags have been effectively used on construction sites dredging locations ponds or in. The solids stay inside the bag. Bag filter is supported by a metal mesh basket in the housing.

These tops typically are. Filter bags for the adapter head system can be of any combination of mediamicron. Quick Easy Shipping.

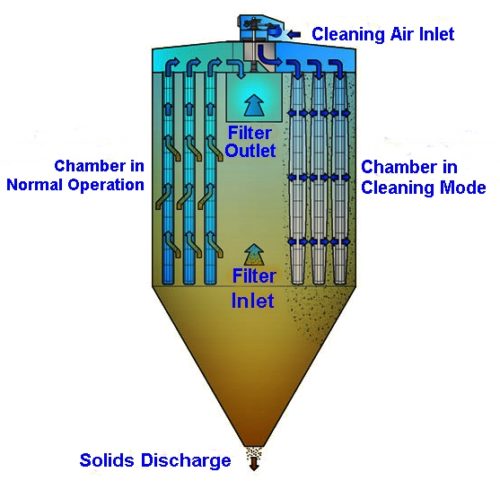

A bag filter normally has a connection for a high-pressure inlet on the top and filtrates exit at the sides and bottom. How to Use Dewatering Bags. Our secret has been to constantly evolve with technology and search for improvements to provide our customers with optimum.

Most bags are either completely or partially made by weaving since nonwoven fabrics are generally attached to a woven base called a scrim. ASME-Code Metal Filter Bag Housings Constructed for use with liquids and gases in boilers and pressure vessels. These filters are commonly called baghouses.

Ad All Types of Bag Filter Housings. Ad Menardi is your expert for cartridge and bag filter solutions. Another design incorporates a molded plastic top.

Impurities are intercepted in the filter bag and housing can be used after changing the filter bag. Sediment Filter Bags are low cost solutions for any construction site or work area looking to control pollution from construction runoff or stormwater runoff. The liquid flows in from the inlet and flows out from the outlet after filtered by the bag.

Bag filters similar to cartridge filters have various configurations and materials of construction yet the flow in this process is inside-to-outside. Dewatering bags are a small and economical solution for any site dealing with storm water runoff dewatering or filtration. ASME-Code Metal Filter Bag Housings Constructed for use with liquids and gases in boilers and pressure vessels.

Bag Filters baghouses have been our core product for over 30 years. Bag Filter for Sludge Dewatering Filtration. With our own proprietary technology our Bag Filters offer the highest particulate removal efficiency on the market far exceeding the most stringent emissions regulations worldwide.

Selection of the correct bag material incorporates these factors. Metal strainer baskets may also be used. Removal of the bag is quick and easy with no clamps to undo or tools required.

Dewatering bags are made of durable geotextile fabric used to filter water by removing sediments. The bag material or fabric media is an important part of baghouse design and selection as it determines the life and effectiveness of the filter bag. Woven fabric handles are also sewn.

The main element of the bag filter systems is the filter bag. Ad high temperature dust filter bags PTFE teflon felt bag filter nomex aramid bag filter. They are installed by simply sliding the ring over the adapter head and securing the bag creating a positive seal.

The operating principle of the bag filter housing is pressure filtration and is a new type of filtration system. Aluminum filter bag housings are lighter weight than steel or stainless steel but still provide good corrosion resistance.

Pulse Jet Bag Filters The Ultimate Faq Guide Filson Filter

Construction And Working Of Bag Filter Solution Pharmacy

Bag Filter An Overview Sciencedirect Topics

Bag Filter Pharmacy Gyan Principle Construction And Working

How Does Bag Filter Work Structure Principle Technology Information Matsushima Measure Tech Co Ltd 株式会社マツシマメジャテック

Baghouse What Is It How Does It Work Uses Types Of

Bag Filter In Boilers Bag Filters Working Principle Thermodyne Boilers

0 comments

Post a Comment